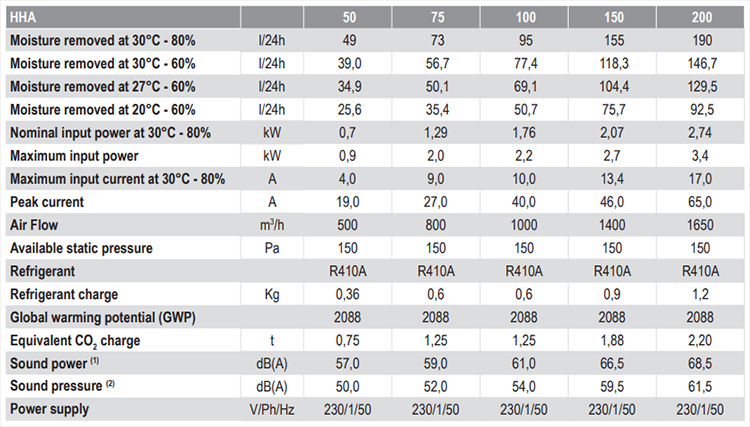

Idrolab IHD 150 - 150LPD Dehumidifier by Idrolab

Idrolab IHD 150 - 150LPD Dehumidifier by Idrolab

-

£8,127.95

In Stock

HOUSING

All the units are made in galvanized sheet metal and oven painted with polyurethane powders at 180 °C to guarantee the best resistance to environmental factors.

The housing is self-standing with removable panels to facilitate inspections and maintenance of inner components.

All the screws are stainless steel coated.

REFRIGERANT CIRCUIT

The refrigerant circuit is produced using components from primary international companies with braze-soldering complying with ISO97/23. Refrigerant gas is R410A.

The refrigerant circuit includes:

- Liquid indicator, dehydrating filter

- Thermostatic valve with external equalization

- Shrader valves for maintenance and control

- Security device (according to PED legislation)

All the units are provided with injection valves kit for hot gas defrosting cycles.

INLET FAN

Fans are made with galvanized steel and are of centrifugal type with forward blades. They are all statically and dynamically balanced. All the electrical motors are connected directly with fans.

They have 3 speeds with integrated thermal protection.

All the motors comply with IP 54 protection standard.

MICROPROCESSOR

All the unites are equipped with a microprocessor for compressor timing control, defrosting cycles and alarms. A specific display with led spies will show the functioning status of the unit and the eventual problems.

SAFETY AND PROTECTION DEVICE

All the units are equipped with the following control and protection devices:

- Temperature probe to signal through the microprocessor the need for a start and end of defrosting cycle

- High pressure pressostat with automatic reset

- Thermal protection for compressors

- Thermal protection for vents

COMPRESSOR

Compressors are rotary with resistant crankcase and protection thermal relay sunk in electrical windings.

Compressors are installed on anti-vibration rubber pads and are provided with a protection cap to reduce sound level.

It is possible to inspect the compressor through the unit’s frontal panel that allows maintenance also with operating machine.

CONDENSERS AND EVAPORATORS

Condensing and evaporating coils are made with brass pipes and aluminum fins. All the evaporators are painted with epoxy powder to prevent problems when the units are used in aggressive environment.

Brass pipes have a diameter of 3/8” and the thickness of aluminum fins is 0,1mm. Pipes are mechanically expanded in aluminum fins to enhance thermal exchange.

The geometry of such exchangers allows for a minimal loss of inlet air loading and so enables the unit to use vents with lower rounds per minute (with consequent reduction in sound level of the unit).

All the units are equipped with stainless steel coated integrated drip trays. Each evaporating coil is equipped with a temperature probe that is used for automatic defrosting.

AIR FILTER

The air filter is included with the unit and it is made in static-charge protected filtering synthetic fiber, removable for specific disposal and class G5 according to EN 779:2002.

ELECTRICAL PANEL

Electrical panel comply with EU legislation 72/23 and 89/336. Accessibility to electrical panel is possible through the frontal panel of the unit and it is protected with a door-lock general switch.

All the HHA units comes with: door-lock circuit breaker, automatic circuit breaker for vents and compressors, fan relays, auxiliary circuits fuses, compressor relay.

Electrical panel is also equipped with a terminal block with free contacts for remote ON-OFF.

TEST

All the units are entirely factory assembled and wired, tested for leakage, vacuum cycle and loaded with refrigerant gas R410A.

All the units undergo a complete live test before shipping. All the units comply with EU legislation and are provided with CE mark and certificate of conformity.

HYGR – Remote mechanical humiditstat

For wall installation in the environment where humidity control is required. It is equipped with control knob for ranges between 30% and 100% with a precision of 3%.

INSE – SERIAL INTERFACE CARD RS485

Factory-assembled temperature/humidity electronic probe on the side of the housing. Not for remote control.

RGDD – TEMPERATURE AND HUMIDITY ELECTRONIC PROBE

Sonda elettronica temperatura/umidità installata in fabbrica a bordo macchina. La sonda non è remotabile.

KGBH – Grids and sub-frame kit for duct installations

Air grids kit with double directional fins made with brushed aluminum and sub-frame for wall fastening.

V1CE – INLET E.C. VENT

Inlet vent is a high performance centrifugal type, double inlet direct coupling and forward blades orientation. Archimedean screw and impeller in galvanized sheet metal painted with polyurethane powder to guarantee best resistance in aggressive environment.

Impeller is assembled directly over the brush-less DC motor with external rotor to guarantee the ideal cooling of the motor and prevention of losses by belt transmission.

Impeller is dynamically balanced, class 6.3 according to ISO 1940. Brush-less DC motor with high efficiency permanent magnets and separated electronic switching unit (driver).

Continuous variable speed with 0-10V signal voltage, integrated PFC, burnout protection (against excessive brownout), IP54 driver, serial interface communication protocol Modbus RTU.

The color of the housing is RAL9018.

Tags: Idrolab, IHD, 150LPD, Dehumidifier

Q & A

Be the first to ask a question.